Hyundai Venue: Rear Drum Brake / Repair procedures

| Removal |

|

| 1. |

Loosen the wheel nuts slightly.

Raise the vehicle, and make sure it is securely supported.

|

| 2. |

Remove the rear wheel and tire (A) from the rear hub.

|

| 3. |

Loosen the screw and then remove the rear drum brake (A).

|

| 4. |

Remove the upper shoe return spring (A).

|

| 5. |

Remove the lower shoe return spring (A).

|

| 6. |

Remove the adjster spring (A).

|

| 7. |

Remove the shoe holder (A) and then remove the rining.

|

| 8. |

Disconnect the parking brake cable (A) from lining (B).

|

| 9. |

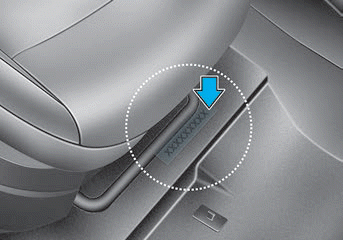

Disconnect brake tubes (A) from the wheel cylinder (B).

|

| 10. |

Remove the bolt (C) and the wheel cylinder (B) from the backing plate

(D).

|

| Installation |

|

| 1. |

Apply sealant (C) between the wheel cylinder (B) and backing plate (D),

and install the wheel cylinder.

|

| 2. |

Connect the brake tubes (A) to the wheel cylinder.

|

| 3. |

Connect the parking brake cable (A) to the brake shoe (B).

|

| 4. |

Install the brake shoes (C) onto the backing plate. Be careful not to

damage the wheel cylinder dust covers.

|

| 5. |

Install the shoe hole down pins (B) and the shoe hole down springs (A).

|

| 6. |

Clean the threaded portions of adjuster sleeve (A) and push rod female

(B). Coat the threads of the adjuster assembly with grease. To shorten

the clevises, turn the adjuster bolt (C).

|

| 7. |

Hook the shoe adjuster lever (C), then install it to the brake shoe.

|

| 8. |

Install the adjuster assembly (B) and upper return spring (A) as right

direction. Be careful not to damage the wheel cylinder dust covers.

|

| 9. |

Install the adjster spring (A).

|

| 10. |

Install the lower return spring (B).

|

| 11. |

Apply brake cylinder grease or equivalent rubber grease to the sliding

surfaces shown. Don't get grease on the brake linings.

|

| 12. |

Apply brake cylinder grease or equivalent rubber grease to the brake

shoe ends and opposite edges of the shoes shown. Don't get grease on

the brake linings.

|

| 13. |

Install the rear brake drum (A).

|

| 14. |

Install the rear wheel and tire (A).

|

| 15. |

Depress the brake pedal several times to set the self-adjusting brake.

|

| Inspection |

|

|

| 1. |

Raise the rear of the vehicle, and make sure it is securely supported.

|

| 2. |

Release the parking brake, and remove the rear brake drum.

|

| 3. |

Check the wheel cylinder (A) for leakage.

|

| 4. |

Check the brake linings (B) for cracking, glazing, wear, and contamination.

|

| 5. |

Measure the brake lining thickness (C). Measurement does not include

brake shoe thickness.

|

| 6. |

If the brake lining thickness is less than the service limit, replace

the brake shoes as a set.

|

| 7. |

Check the bearings in the hub unit for smooth operation. If it requires

servicing, replace it.

|

| 8. |

Measure the inside diameter of the brake drum with inside vernier calipers.

|

| 9. |

If the inside diameter of the brake drum is more than the service limit,

replace the brake drum.

|

| 10. |

Check the brake drum for scoring, grooves, and cracks.

|

| 11. |

Inspect the brake lining and drum for proper contact.

|

| 12. |

Inspect the wheel cylinder outside for excessive wear and damage.

|

| 13. |

Inspect the backing plate for wear or damage.

|

Components and components location

Components and components location

Components

1. Upper return spring

2. Shoe adjuster

3. Adjusting lever

4. Shoe hold down pin

5. Shoe hold spring

6...

Other information:

Hyundai Venue (QX) (2020-2025) Service Manual: Smart Key. Repair procedures

Smart Key Smart Key Code Saving 1. Connect the DLC cable of GDS to the data link connector (16 pins) in driver side crash pad lower panel, turn the power on GDS. 2. Select the 'S/W Management' and 'Car model'...

Hyundai Venue (QX) (2020-2025) Service Manual: General information

General Information The supplemental restraint system (SRS) is designed to supplement the seat belt to help reduce the risk or severity of injury to the driver and passenger by activating and deploying the driver, passenger, side airbag and belt pretensioner in certain frontal or side collisions...

Categories

- Manuals Home

- 1st Generation Venue Owners Manual

- 1st Generation Venue Service Manual

- Trip Computer

- Electronic Stability Control (ESC)

- Shift-lock system, Shift-lock release, Parking

- New on site

- Most important about car

Vehicle Identification Number (vin), Vehicle Certification Label

Vehicle Identification Number (vin)

Frame number

Copyright © 2025 www.hvenueqx.com