Hyundai Venue: Hydraulic System / Underdrive Brake Control Solenoid Valve (UD/B_VFS). Repair procedures

| • |

Refer to the DTC manual for the check procedure.

|

|

| • |

When the solenoid valve Diagnostic Trouble Codes (DTC) is on,

perform the following procedure to replace it.

|

| • |

Automatic transaxle is composed of delicate components. Be careful

not to cause any damage on the component in the course of assembly

and disassembly.

|

| • |

Maintain clean condition so that foreign substance does not

get into the automatic transaxle.

|

| • |

Use a coated apron, latex gloves, and stainless tray to prevent

foreign substance from getting into the transaxle.

|

| • |

Automatic transaxle fluid (ATF) can be reused. Collect it using

a clean 10-liter beaker.

|

|

| 1. |

Turn ignition switch OFF and disconnect the negative (-) battery cable.

|

| 2. |

Remove the air cleaner and air duct.

| (1) |

Remove the air duct (A).

|

| (2) |

Disconnect the breather hose (B) and air intake hose (C).

|

| (3) |

Remove the air cleaner assembly (D).

|

Tightening torque :

Hose clamp bolt (C):

2.9 - 4.9 N.m (0.3 - 0.5 kgf.m, 2.1 - 3.6 lb-ft)

Air cleaner assembly bolts (D) :

3.9 - 5.9 N.m (0.4 - 0.6 kgf.m, 2.9 - 4.3 Ib-ft)

|

|

|

| 3. |

Discharge the automatic transaxle fluid (ATF).

(Refer to Automatic Transaxle Syatem - "Automatic Transaxle Fluid (ATF)")

|

| 4. |

Disconnect the wiring fixing clip (A).

|

| 5. |

Disconnect the air bleeder hose (B).

|

| 6. |

Disconnect the ATF cooler hose (A).

| •

|

Be careful not to cause any damage on the hose when

tightening the clamp.

|

| •

|

Mount the clamp tightening part in the designated direction

so that interference does not occur with the adjacent

parts.

|

| •

|

After connecting the hose, check for oil leakage on

the connecting part while the engine is on.

|

|

|

| 7. |

Unscrew the bolts and remove the valve body cover (A).

|

Tightening torque :

11.8 - 13.7 N.m (1.2 - 1.4 kgf.m, 8.7 - 10.1 lb-ft)

|

| •

|

When re-mounting the valve body cover, replace the gasket

with a new one.

|

| •

|

After mounting the valve body cover, check for oil leakage

on the connecting part while the engine is on.

|

|

|

| 8. |

Unscrew the bolts and disconnect the solenoid valve connector (A).

|

Tightening torque :

9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)

|

|

| 9. |

Remove the support bracket (A).

|

Tightening torque :

9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)

|

|

| 10. |

Remove the roller (A) and bolt (B).

|

Tightening torque :

9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)

|

|

| 11. |

Remove the underdrive brake control solenoid valve (A).

|

| • |

Note the value carefully and check the value again before assembly.

|

| • |

Inputting an invalid value (A) may cause the abnormal shifting

shock while TCM learning.

|

|

| 1. |

To install, reverse the removal procedure.

|

| 2. |

Inject the automatic transaxle oil and inspect the oil level.

(Refer to Automatic Transaxle System - "Automatic Transaxle Fluid (ATF)")

| 1) |

After ATF level check or exchange, be sure to remove

residual ATF on transaxle case.

(Be especially sure to remove residual ATF between automatic

transaxle case and valve body cover)

|

| 2) |

After installing the valve body cover, make sure to

check the oil leakage at the connection area with the

engine ON.

|

|

|

| 3. |

Clear the diagnostic trouble codes (DTC) using the diagnostic tool.

| •

|

Even though disconnecting the battery negative terminal,

the DTCs will not be cleared. So, be sure to clear the

DTCs using the diagnostic tool.

|

|

|

| 4. |

Reset the automatic transaxle adaptive values using the diagnostic tool.

|

| 5. |

Input the oil pressure characteristics using the diagnostic tool.

| (1) |

Select ‘Oil-pressure Characteristics (Solenoid Valve Replacement)’

in the S/W Management.

|

| (2) |

Select the replaced solenoid valve.

|

| (3) |

Check the code marked on the solenoid valve.

|

| (4) |

If the code is inputted 2 times correctly, the procedure is

completed.

|

|

| 6. |

In order to prevent start delay and gear shift shock during acceleration

and start, perform TCM learning after replacing the solenoid valve.

(Refer to Automatic Transaxle Control System - "Repair procedures")

|

Component Location (1)_Valve

Body Cover

1. Valve Body Cover

2. Valve Body Cover Gasket

3. Solenoid Valve Connector

Component Location (2)_Solenoid

Valve

1...

Description

•

Overdrive clutch control solenoid valve(OD/C_VFS) is attached to the

valve body.

•

This variable force solenoid valve directly controls the hydraulic pressure

inside the overdrive clutch...

Other information:

WARNING

Before installing your child restraint system always:

Read and follow the instructions provided by the manufacturer of the

child restraint.

Read and follow the instructions regarding child restraint systems in

this manual.

Failure to follow all warnings and instructions could increase the risk of

the SERIOUS INJURY or DEATH if an accident occurs...

Removal

1.

Remove the fuel pump.

(Refer to Fuel Delivery System - "Fuel Pump")

2.

Disconnect the electric pump wiring connector (A) and the fuel sender

connector (B)...

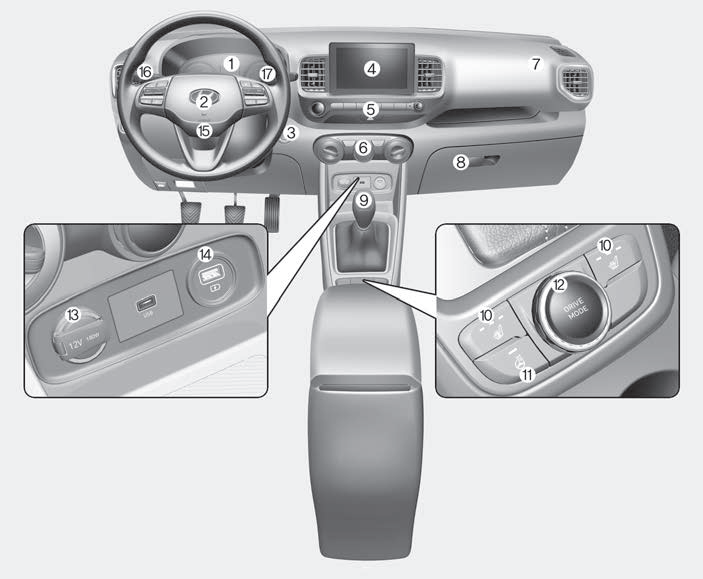

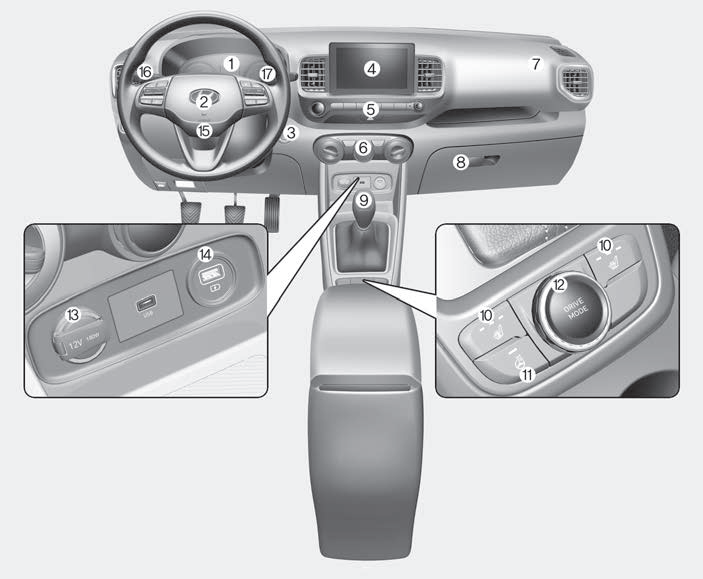

Categories

1. Instrument cluster

2. Horn

3. Key ignition switch/ Engine Start/Stop button

4. Infotainment system

5. Hazard warning flasher switch

read more

Underdrive Brake Control Solenoid Valve (UD/B_VFS). Components and components

location

Underdrive Brake Control Solenoid Valve (UD/B_VFS). Components and components

location Overdrive Clutch Control Solenoid Valve (OD/C_VFS). Description and operation

Overdrive Clutch Control Solenoid Valve (OD/C_VFS). Description and operation