Hyundai Venue: Automatic Transaxle Control System / Transaxle Control Module (TCM). Repair procedures

Hyundai Venue (QX) (2020-2025) Service Manual / Automatic Transaxle System / Automatic Transaxle Control System / Transaxle Control Module (TCM). Repair procedures

| Inspection |

▶ Transaxle Control Module(TCM) Problem Inspection Procedure

| 1. |

TEST TCM GROUND CIRCUIT: Measure resistance between TCM and chassis

ground using the backside of TCM harness connector as TCM side check

point. If the problem is found, repair it.

|

| 2. |

TEST TCM CONNECTOR: Disconnect the TCM connector and visually check

the ground terminals on TCM side and harness side for bent pins or poor

contact pressure. If the problem is found, repair it.

|

| 3. |

If problem is not found in Step 1 and 2, the TCM could be faulty. If

so, make sure there were no DTC's before swapping the TCM with a new

one, and then check the vehicle again. If DTC's were found, examine

this first before swapping TCM.

|

| 4. |

RE-TEST THE ORIGINAL TCM: Install the original TCM (may be broken) into

a known-good vehicle and check the vehicle. If the problem occurs again,

replace the original TCM with a new one. If problem does not occur,

this is intermittent problem (Refer to “Intermittent Problem Inspection

Procedure” in Basic Inspection Procedure).

|

| Removal |

| 1. |

Perform the oil pressure characteristics backup procedure using the

diagnostic tool when replacing with a new TCM.

|

| 2. |

Turn ignition switch OFF.

|

| 3. |

Disconnect the battery (-) terminal (A).

|

| 4. |

Disconnect the battery (+) terminal (B).

|

| 5. |

Remove the battery mounting bracket (A) and the battery (B).

|

| 6. |

Disconnect the TCM connector (A).

|

| 7. |

Remove the bolts (A) and nut (B).

|

| 8. |

Remove the TCM (C).

|

| Installation |

| 1. |

To install, reverse the removal procedure.

|

| 2. |

Oil-pressure characteristics input (TCM exchange)

|

| 3. |

Perform the procedures related in the ECM after replacing the TCM.

(Refer to Engine Control / Fuel System - "Engine Control Module")

|

| 4. |

Perform TCM learning after replacing the transaxle to prevent slow transaxle

response, jerky acceleration and jerky startup.

(Refer to Automatic Transaxle Control System - "Repair procedures")

|

Transaxle Control Module (TCM). Schematic diagrams

Transaxle Control Module (TCM). Schematic diagrams

TCM Connector

Connector [A]

Pin

Description

2

35R clutch control solenoid valve (35R/C_VFS)

4

26 brake control solenoid valve (26/B_VFS)

5

Underdrive brake control solenoid valve (UD/B_VFS)

8

Inhibitor switch signal S2 (R)

19

Line pressure control solenoid valve (LINE_VFS)

21

Input speed sensor power

22

Output speed sensor power

32

Torque converter control solenoid valve (T/CON_VFS)

33

VB (Battery voltage)

34

Solenoid supply power 2

37

Output speed sensor signal

38

Inhibitor switch signal S4 (D)

39

Inhibitor switch signal S1 (P)

40

Manual mode up shift

42

Manual mode select switch

43

Oil temperature sensor (+)

45

VB (Battery voltage)

46

ON/OFF solenoid valve A(SS-A)

47

Overdrive clutch control solenoid valve (OD/C_VFS)

48

VB (Battery voltage)

49

Solenoid supply power 1

52

Input speed sensor signal

54

Inhibitor switch signal S3 (N)

57

Manual mode down shift

58

Oil temperature sensor (-)

TCM Terminal input/ output signal

Connector [A]

Pin

Description

Condition

Input/output value

Type

Level

2

35R clutch control solenoid valve

(35R/C_VFS)

-

Output

0V/Battery voltage level

9V < Battery voltage level < 16V

4

26 brake control solenoid valve

(26/B_VFS)

-

Output

0V/Battery voltage level

9V < Battery voltage level < 16V

5

Underdrive brake control solenoid valve

(UD/B_VFS)

-

Output

0V/Battery voltage level

9V < Battery voltage level < 16V

8

Inhibitor switch signal S2 (R)

High

Input

0V/Battery voltage level

Low

9V < Battery voltage level < 16V

19

Line pressure control solenoid valve

(LINE_VFS)

-

Output

0V/Battery voltage level

9V < Battery voltage level < 16V

21

Input speed sensor power

ON

Power

0V/9V

OFF

22

Output speed sensor power

ON

Power

0V/9V

OFF

32

Torque converter control solenoid valve

(T/CON_VFS)

-

Output

0V/Battery voltage level

9V < Battery voltage level < 16V

34

Solenoid power 2

Power

0V/Battery voltage level

9V < Battery voltage level < 16V

37

Output speed sensor signal

High

Input

0...

Transaxle Oil Temperature Sensor. Description and operation

Transaxle Oil Temperature Sensor. Description and operation

Description

•

Transaxle oil temperature sensor monitors the automatic transaxle fluid's

temperature and conveys the readings to TCM...

Other information:

Hyundai Venue (QX) (2020-2025) Service Manual: Delivery Pipe. Repair procedures

Removal 1. Release the residual pressure in fuel line. (Refer to Fuel Delivery System - "Release Residual Pressure in Fuel Line") 2. Turn the ignition switch OFF and disconnect the battery negative (-) terminal...

Hyundai Venue (QX) (2020-2025) Service Manual: Sunroof Deflector. Repair procedures

Replacement 1. Open the glass fully. 2. Remove the mounting bolt (C), from the frame (B), and then remove the deflector (A). 3. To install, reverse the removal procedure...

Categories

- Manuals Home

- 1st Generation Venue Owners Manual

- 1st Generation Venue Service Manual

- Smart Key

- Immobilizer System

- Warning and Indicator Lights

- New on site

- Most important about car

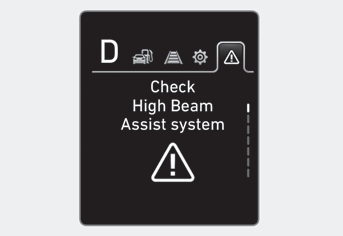

Master warning mode

This warning light informs the driver the following situations.

-- Forward Collision-Avoidance Assist system malfunction (if equipped)

-- Forward Collision-Avoidance Assist radar blocked (if equipped)

-- Blind-Spot Collision Warning system malfunction (if equipped)

-- Blind-Spot Collision Warning radar blocked (if equipped)

-- Lamp malfunction (if equipped)

-- High Beam Assist malfunction (if equipped)

-- Tire Pressure Monitoring System (TPMS) malfunction (if equipped)

Copyright © 2025 www.hvenueqx.com