Hyundai Venue: Timing System / Timing Chain Cover. Repair procedures

Hyundai Venue (QX) (2020-2025) Service Manual / Engine Mechanical System / Timing System / Timing Chain Cover. Repair procedures

| Removal |

|

|

| 1. |

Remove the drive belt.

(Refer to Timing System - "Drive Belt")

|

| 2. |

Remove the drive belt idler.

(Refer to Timing System - "Idler")

|

| 3. |

Remove the alternator.

(Refer to Engine Electrical System - "Alternator")

|

| 4. |

Remove the alternetor bracket.

(Refer to Timing Systme - "Drive Belt Tensioner")

|

| 5. |

Remove the engine room under cover.

|

| 6. |

Remove the crankshaft damper pulley.

(Refer to Timing System - Crankshaft Damper Pulley")

|

| 7. |

Remove the water pump.

(Refer to Cooling System - "Water Pump")

|

| 8. |

Remove the air cleaner assembly.

(Intake and Exhaust System - "Air Cleaner")

|

| 9. |

Remove the cylinder head cover.

(Refer to Cylinder Head Assembly - "Cylinder Head Cover")

|

| 10. |

Remove the engine mounting support bracket.

|

| 11. |

Remove the Engine support bracket (A).

|

| 12. |

Remove the Timing Chain Cover (A).

|

| Installation |

| 1. |

Install the timing chain cover (A).

|

| 2. |

Install the engine support bracket (A).

|

| 3. |

Installation is reverse order of removal.

|

Other information:

Hyundai Venue (QX) (2020-2025) Service Manual: Transaxle Control Module (TCM). Description and operation

Description • Monitors the vehicle's operating conditions to determine the optimal gear setting. • Performs a gear change if the current gear setting differs from the identified optimal gear setting...

Hyundai Venue (QX) (2020-2025) Service Manual: Troubleshooting

..

Categories

- Manuals Home

- 1st Generation Venue Owners Manual

- 1st Generation Venue Service Manual

- Liftgate

- Vehicle Identification Number (vin), Vehicle Certification Label

- Electronic Stability Control (ESC)

- New on site

- Most important about car

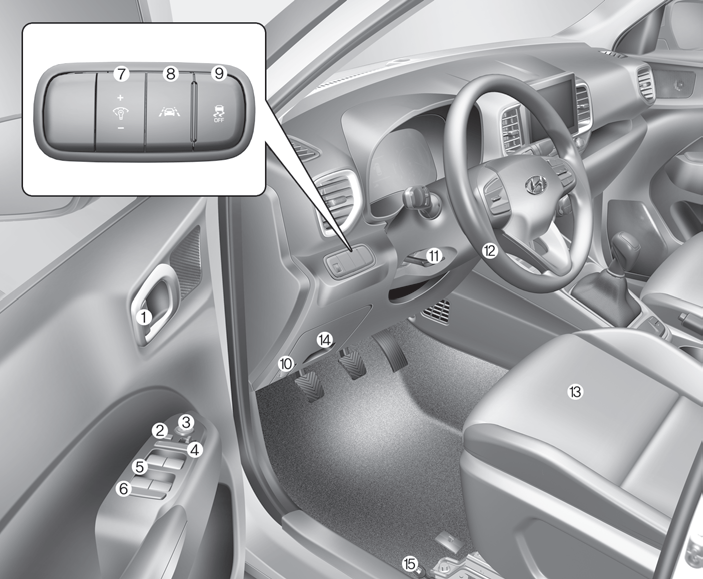

Interior Overview

1. Door lock/unlock button

2. Outside rearview mirror control switch

3. Central door lock switch

4. Power window switches

5. Power window lock switch

Copyright © 2025 www.hvenueqx.com