Hyundai Venue: Starter / Repair procedures

Hyundai Venue (QX) (2020-2025) Service Manual / Engine Electrical System / Starting System / Starter / Repair procedures

| Removal |

| 1. |

Turn the ignition switch OFF and disconnect the battery negative (-)

terminal.

|

| 2. |

Remove the air cleaner assembly.

(Refer to Engine Mechanical System - "Air Cleaner")

|

| 3. |

Disconnect the starter cable (B) from the B - terminal on the solenoid

and the connector (A) from the S terminal.

|

| 4. |

Remove the starter bolt (A).

|

| 5. |

Remove the starter.

|

| Installation |

| 1. |

Install in the reverse order of removal.

|

| Disassembly |

| 1. |

Disconnect the M-terminal (A) on the magnet switch assembly.

|

| 2. |

After loosening the screws (A), detach the magnet switch ssembly (B).

|

| 3. |

Loosen the brush mounting screw (A) and through bolts (B).

|

| 4. |

Remove the rear bracket (A) brush holder assembly (B).

|

| 5. |

Remove the yoke (A).

|

| 6. |

Remove the packing (A), lever plate (B), lever (C) and the rmature (D).

|

| 7. |

Press the stopper (A) using a socket (B).

|

| 8. |

After removing the stop ring (A) using stop ring pliers (B).

|

| 9. |

Disconnect the stop ring (B), stopper (A), overrunning clutch (C) and

armature (D).

|

| 10. |

Reassembly is the reverse of disassembly.

|

| Reassembly |

| 1. |

Reassemble in the reverse order of disassembly.

|

| Inspection |

| Starter Solenoid Inspection |

| 1. |

Disconnect the lead wire from the M-terminal of solenoid switch.

|

| 2. |

Connect the battery as shown. If the starter pinion pops out, it is

working properly.

|

| 3. |

Disconnect the battery from the M terminal.

If the pinion does not retract, the hold-in coil is working properly.

|

| 4. |

Disconnect the battery also from the body. If the pinion retracts immediately,

it is working properly.

|

| Free Running Inspection |

| 1. |

Place the starter motor in a vise equipped with soft jaws and connect

a fully-charged 12-volt battery to starter motor as follows.

|

| 2. |

Connect a test ammeter (150-ampere scale) and carbon pile rheostats

shown is the illustration.

|

| 3. |

Connect a voltmeter (15-volt scale) across starter motor.

|

| 4. |

Rotate carbon pile to the off position.

|

| 5. |

Connect the battery cable from battery's negative post to the starter

motor body.

|

| 6. |

Adjust until battery voltage shown on the voltmeter reads 11.5volts.

|

| 7. |

Confirm that the maximum amperage is within the specifications and that

the starter motor turns smoothly and freely.

|

Armature Inspection and Test

| 1. |

Remove the starter.

|

| 2. |

Disassemble the starter as shown at the beginning of this procedure.

|

| 3. |

Inspect the armature for wear or damage from contact with the permanent

magnet. If there is wear or damage, replace the armature.

|

| 4. |

Check the commutator (A) surface. If the surface is dirty or burnt,

resurface with emery cloth or a lathe within the following specifications,

or recondition with #500 or #600 sandpaper (B).

|

| 5. |

Check the commutator diameter. If the diameter is below the service

limit, replace the armature.

|

| 6. |

Measure the commutator (A) runout.

|

| 7. |

Check the mica depth (A). If the mica is too high (B), undercut the

mica with a hacksaw blade to the proper depth. Cut away all the mica

(C) between the commutator segments. The undercut should not be too

shallow, too narrow, or v-shaped (D).

|

| 8. |

Check for continuity between the segments of the commutator. If an open

circuit exists between any segments, replace the armature.

|

| 9. |

Check with an ohmmeter that no continuity exists between the commutator

(A) and armature coil core (B), and between the commutator and armature

shaft (C). If continuity exists, replace the armature.

|

Inspect Starter Brush

Brushes that are worm out, or oil-soaked, should be replaced.

Starter Brush Holder Test

Make sure there is no continuity between the (+) brush holder (A) and (-) plate

(B). If there is continuity, replace the brush holder assembly.

Overrunning Clutch

| 1. |

Slide the overrunning clutch along the shaft.

Replace it if does not slide smoothly.

|

| 2. |

Rotate the overrunning clutch both ways.

Does it lock in one direction and rotate smoothly in reverse? If it

does not lock in either direction or it locks in both directions, replace

it.

|

| 3. |

If the starter drive gear is worn or damaged, replace the overrunning

clutch assembly. (the gear is not available separately).

Check the condition of the flywheel or torque converter ring gear if

the starter drive gear teeth are damaged.

|

| Cleaning |

| 1. |

Do not immerse parts in cleaning solvent.

Immersing the yoke assembly and/or armature will damage the insulation

wipe these parts with a cloth only.

|

| 2. |

Do not immerse the drive unit in cleaning solvent.

The overrun clutch is pre-lubricated at the factory and sol-vent will

wash lubrication from the clutch.

|

| 3. |

The drive unit may be cleaned with a brush moistened with cleaning solvent

and wiped dry with a cloth.

|

Starter Relay. Repair procedures

Starter Relay. Repair procedures

Inspection

1.

Disconnect the battery negative terminal.

2.

Remove the fuse box cover.

3...

Other information:

Hyundai Venue (QX) (2020-2025) Service Manual: Rear Wheel Speed Sensor. Repair procedures

Removal [Rear Drum Brake Type] 1. Loosen the wheel nuts slightly. Raise the vehicle, and make sure it is securely supported. 2. Remove the rear wheel and tire (A) from the rear hub...

Hyundai Venue (QX) (2020-2025) Service Manual: Troubleshooting

..

Categories

- Manuals Home

- 1st Generation Venue Owners Manual

- 1st Generation Venue Service Manual

- System Setting and Activation

- Vehicle Identification Number (vin), Vehicle Certification Label

- Operating Door Locks from Outside the Vehicle

- New on site

- Most important about car

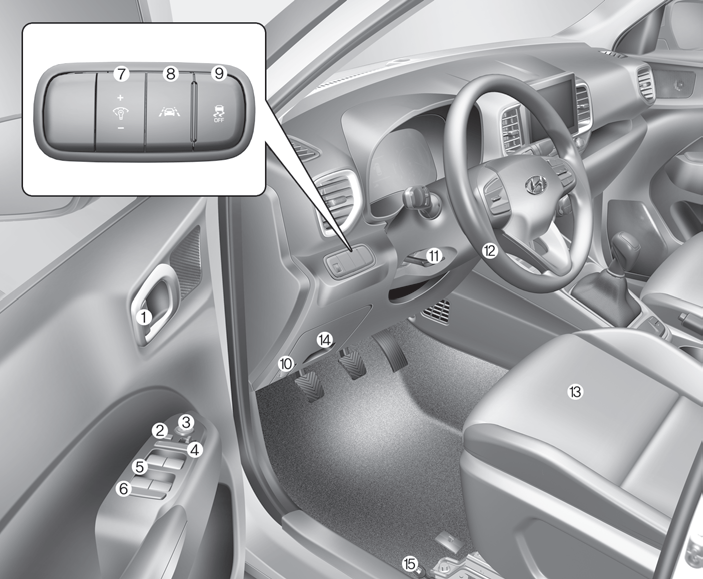

Interior Overview

1. Door lock/unlock button

2. Outside rearview mirror control switch

3. Central door lock switch

4. Power window switches

5. Power window lock switch

Copyright © 2025 www.hvenueqx.com