Hyundai Venue: Automatic Transaxle Control System / Inhibitor Switch. Repair procedures

▶ Inspection flow of the inhibitor switch

▶ Items to check

| 2. |

Inspect whether N setting matches.

| – |

Adjust N setting (refer to automatic transmission system - "inhibitor

switch")

|

|

| 3. |

Inspect shift cable separation.

| – |

Adjust shift cable separation (refer to automatic transmission

system - "shift cable")

|

|

| 4. |

Inspect whether connector is connected.

| – |

Inspect connector thoroughly for looseness, poor connection,

bending, corrosion, contamination, deformation, or damage.

|

| – |

Turn ignition key "ON" and engine "OFF" and measure the power

supplied to inhibitor switch circuit and voltage between ground.

|

Specification : approx. 12V

|

|

| – |

Fix the pin wiring when connector pin wiring is faulty.

(Refer to ETM - "wiring repair").

|

|

| 5. |

Inspect ground condition on reversing light circuit.

| – |

Check the ground location of reversing light (refer to ETM -

"harness location map").

|

| – |

Reattach reversing light if ground condition is faulty.

|

|

| 6. |

Inspect wiring connection on junction box power terminal and fuse lamp.

| – |

Check whether fuse holder is separated and holder is holding

the fuse tight.

|

| – |

Attach tester fuse to check if it is connected appropriately.

|

| – |

Check whether fuse capacity is appropriate for each circuit.

|

| – |

Check if fuse is damaged.

|

| – |

Check pulling of fuse fixing wiring, inflow of foreign substance,

and arrangement condition of terminal.

|

| – |

Relocate the terminal that has been pulled and inspect using

the method explained above.

|

| – |

When problem is not solved, refer to the circuit diagram wiring

repair instructions to fix or replace the terminal.

|

|

| 7. |

Inspect inhibitor switch signal.

| – |

Turn ignition key "ON" and engine "OFF".

|

| – |

Measure the voltage between each terminal and chassis ground

when shifting lever to "P, R, N, D" range.

|

Specified value : Refer to specification "signal code"

table

|

|

|

| 1. |

Make sure vehicle does not roll before setting shift lever to "N" position.

|

| 2. |

Turn ignition switch OFF and disconnect the negative (-) battery cable.

|

| 3. |

Remove the air cleaner and air duct.

| (1) |

Remove the air duct (A).

|

| (2) |

Disconnect the breather hose (B) and air intake hose (C).

|

| (3) |

Remove the air cleaner assembly (D).

|

Tightening torque :

Hose clamp bolt (C):

2.9 - 4.9 N.m (0.3 - 0.5 kgf.m, 2.1 - 3.6 lb-ft)

Air cleaner assembly bolts (D) :

3.9 - 5.9 N.m (0.4 - 0.6 kgf.m, 2.9 - 4.3 Ib-ft)

|

|

|

| 4. |

Disconnect the inhibitor switch connector (A).

|

| 5. |

Remove the shift cable mounting nut (B).

|

| 6. |

Remove the manual control lever and the washer after removing a nut

(A).

|

| 7. |

Remove the inhibitor switch after removing the bolts (B).

|

| 1. |

Check that the shift lever is placed in the "N" position.

|

| 2. |

Lightly tighten the bolts (A) after installing the inhibitor switch.

|

| 3. |

Lightly tighten the nut (B) after installing the manual control lever.

|

| 4. |

Align the hole in the manual control lever with the "N" position hole

of the inhibitor switch and then insert the inhibitor switch guide pin

(SST No. : 09480 - A3800).

|

| 5. |

Tighten the nut (A) and bolts (B) with the specified torque.

|

Tightening torque :

A : 17.7 - 24.5 N.m (1.8 - 2.5 kgf.m, 13.0 - 18.1 lb-ft)

B : 9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)

|

|

| 6. |

Lightly tighten the nut (A) after connected the shift cable (B) in the

manual control lever (C).

|

| 7. |

Tighten the nut (A) with the specified torque.

|

Tightening torque :

9.8 - 13.7 N.m (1.0 - 1.4 kgf.m, 7.2 - 10.1 lb-ft)

|

|

| 8. |

Remove the inhibitor switch guide pin (SST No. : 09480 - A3800) from

the hole.

|

| 9. |

Connect the inhibitor switch connector (A).

|

| 10. |

Install the air cleaner and air duct.

| (1) |

Install the breather hose (B) and air intake hose (C).

|

| (2) |

Install the air cleaner assembly (D).

|

Tightening torque :

Hose clamp bolt (C):

2.9 - 4.9 N.m (0.3 - 0.5 kgf.m, 2.1 - 3.6 lb-ft)

Air cleaner assembly bolts (D) :

3.9 - 5.9 N.m (0.4 - 0.6 kgf.m, 2.9 - 4.3 Ib-ft)

|

|

| (3) |

Install the air duct (A).

|

|

| 11. |

Connect the battery negative (-) cable.

|

| 12. |

Check that operating surely at each range of the inhibitor switch corresponding

to each position of shift lever.

|

Fault Diagnosis

▶ Fault Diagnosis for Symptom

Major Symptom

Expected Cause

Items to Check and Measures

Shift lever inoperable

Faulty shift cable tension

Adjust shift cable tension

(refer to "Automatic Transaxle System – Inhibitor Switch")

Faulty shift cable assembly/connection

Check manual control valve assembly and re-assemble if necessary...

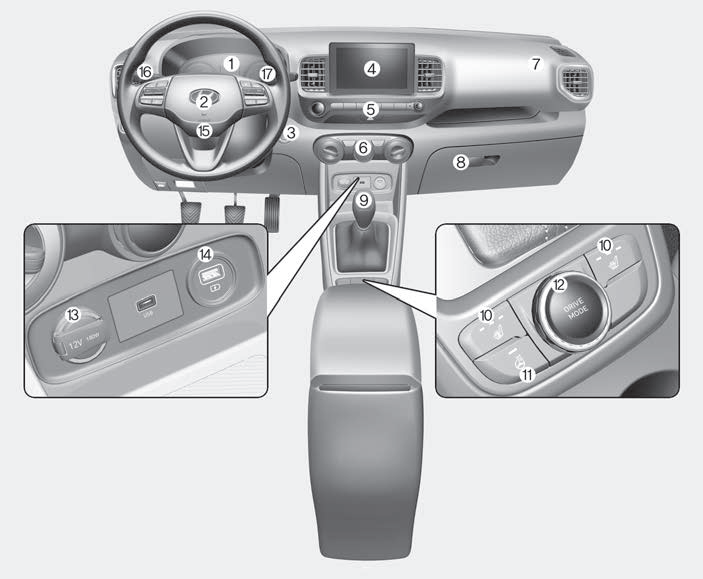

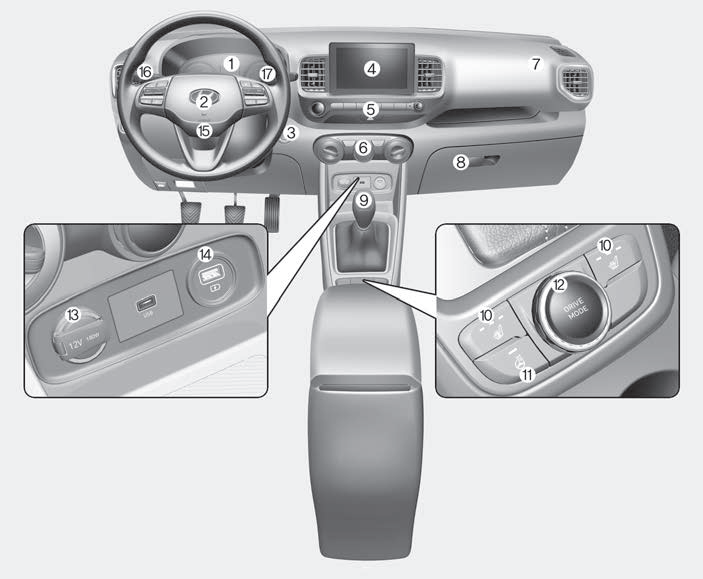

Components Location

1. Shift lever knob & boots

2. Shift lever assembly

3. Shift cable

4. Manual control lever

5...

Other information:

Always set the parking brake before leaving the vehicle. To apply the parking

brake:

Firmly depress the brake pedal. Pull up the parking brake lever as far as possible.

WARNING

To reduce the risk of SERIOUS INJURY or DEATH, do not operate the parking

brake while the vehicle is moving except in an emergency situation...

Removal

1.

Remove the bumper cover.

(Refer to Body - "Front Bumper Cover")

2.

Disconnect the connector (A) from the PDW sensor.

[L - Type]

Installation

1...

Categories

1. Instrument cluster

2. Horn

3. Key ignition switch/ Engine Start/Stop button

4. Infotainment system

5. Hazard warning flasher switch

read more

Inhibitor Switch. Troubleshooting

Inhibitor Switch. Troubleshooting Shift Lever. Components and components location

Shift Lever. Components and components location