Hyundai Venue: Button Engine Start System / Description and operation

Hyundai Venue (QX) (2020-2025) Service Manual / Body Electrical System / Button Engine Start System / Description and operation

| Description |

System Overview

The System offers the following features:

| – |

Human machine interface through a 1-stage button, for terminal switching

and engine start.

|

| – |

Control of external relays for ACC / IGN1 / IGN2 terminal switching

and STARTER, without use of mechanical ignition switch.

|

| – |

Steering column locking with an ESCL device; Monitoring of the vehicle

status to insure safe activation of the ESCL.

|

| – |

Indication of vehicle status through LED or explicit messages on display.

|

| – |

Immobilizer function by LF transponder communication between fob and

start/stop button.

|

| – |

Redundant architecture for high system dependability .

|

| – |

Interface with Low Speed CAN vehicle communication network.

|

| – |

Interface with LIN vehicle communication network depending on platform

.

|

The RKE and SMART KEY functions are not considered part of this Button Engine

Start system and are specified in separated system.

System Main Function

| – |

Steering column locking/unlocking with ESCL.

|

| – |

Switching of ACC / IGN1 / IGN2 terminals.

|

| – |

Control of the STARTER relay BAT line (high side) based on communication

with EMS ECU.

|

| – |

Management of the Immobilizer function.

|

| – |

Management of BES warning function.

|

Button Engine Start System

The Button Start System allows the driver to operate the vehicle by simply pressing

a button (called as SSB) instead of using a standard mechanical key. It also

manages the locking and the unlocking of the steering column (called as ESCL)without

any specific actions by the driver.

If the driver press the SSB while prerequisites on brakes, fob authentication

and transmission status are satisfied, the BES System will proceed with the

locking/unlocking of the steering column, the control of the terminal, and the

cranking of the engine.

The driver can release the SSB as soon as this sequence initiated. After positive

response from immobilizer interrogation, the system will activate the starter

motor and communicate with the EMS to check the engine running status for starter

release.

The driver will be able to stop the engine by a short push on the SSB if the

vehicle is already in standstill. Emergency engine stop will be possible by

a long press of the SSB or 3 consecutive presses in case the vehicle is in ENGINE

RUNNING.

If the conditions for engine cranking are not satisfied while a push on the

SSB is detected and a valid fob authenticated, the system will unlock the steering

column and switch the terminals to IGN. Another push on the SSB will be necessary

to start the engine.

In case of a vehicle equipped with SMART KEY system, fob authentication will

not require any action from the driver. For limp home start or in case of vehicle

without SMART KEY, the driver will have to push the start / stop button.

| • |

Control Ignition and engine ON/OFF by Sending signal to IPM.

|

| • |

Display status by LED Lamp ON/OFF. (Amber or Blue)

|

Indicator ON/OFF Condition at Ignition Key Off Condition

|

No |

Character lamp |

Conditions |

|

1 |

Indicator Lamp ON |

Door open, Tail lamp ON, ACC, IG ON |

|

2 |

Indicator Lamp 30sec ON → Lamp OFF |

Door close, Tail lamp OFF, IG OFF |

|

3 |

Indicator Lamp OFF |

Remote LOCK, Passive LOCK |

|

4 |

Rheostat at tail lamp ON (Illumination lamp) |

|

Indicator ON/OFF Condition According to Ignition Key's Position

|

No |

Ignition conditions |

Start Button LED status |

|

1 |

IG OFF |

LED OFF |

|

2 |

IG ACC |

Amber color LED ON |

|

3 |

IG ON (Engine OFF) |

Blue color LED ON |

|

4 |

Cranking |

Maintain LED status before cranking |

|

5 |

Engine running |

LED OFF |

Wireless Communication

Electromagnetic waves are used to exchange information between the vehicle and

the FOB. Two types of RKE Key can supplement the BES system:

| – |

Non-smart key RKE

|

| – |

SMART KEY FOB

|

Currently the BES system comprises with SMART KEY FOB always.

The transmitter, receiver and antennas required for the communication between

the fob and the vehicle will differ depending on functionalities and regional

areas.

The RKE and SMART KEY functions are in separated documents. Refer to Smart key

system for more detailed information about SMART KEY function.

Smart Key

The IBU manages all function related to:

| • |

"Start Stop Button (SSB) monitoring",

|

| • |

"Immobilizer communication" (with Engine Management System unit for

immobilizer release),

|

| • |

"ESCL control",

|

| • |

"Authentication server" (Validity of Transponder and in case of Smart

Key option Passive Fob authentication ),

|

| • |

"System consistency monitoring",

|

| • |

"System diagnosis",

|

| • |

Control of display message / warning buzzer .

|

The unit behaves as Master role in the whole system.

In case of SMART KEY application, for example “Passive Access”, “Passive Locking”

and “Passive Authorization are integrated for ESCL/Terminal switching Operations”.

It collects information about vehicle status from other modules (vehicle speed,

alarm status, driver door open...), read the inputs (e.g. SSB, Lock Button and

PARK position Switch), controls the outputs (e.g. exterior and interior antennas),

and communicates with others devices via the CAN network as well as a single

line interfaces.

The diagnosis and learning of the components of the BES System are also handled

by the SMK.

Transponder

IBU (Intergrated Bocy Control Unit)

The IBU manages all function related to :

| • |

"Start Stop Button (SSB) monitoring",

|

| • |

"Immobilizer communication" (with Engine Management System unit for

immobilizer release),

|

| • |

"Authentication server" (Validity of Transponder and in case of Smart

Key option Passive Fob authentication ),

|

| • |

"System consistency monitoring",

|

| • |

"System diagnosis",

|

| • |

Control of display message / warning buzzer.

|

The unit behaves as Master role in the whole system.

In case of SMART KEY application, for example "Passive Access”, "Passive Locking”

and "Passive Authorization are integrated for Terminal switching Operations”.

It collects information about vehicle status from other modules (vehicle speed,

alarm status, driver door open...), reads the inputs (e.g. SSB, Capacitive Sensor

/ Lock Button, PARK position Switch), controls the outputs (e.g. exterior and

interior antennas), and communicates with others devices via the CAN network

as well as a single line interfaces.

The diagnosis and learning of the components of the BES System are also handled

by the IBU.

The IBU manages the functions related to the "terminal control" by activating

external relays for ACC, IGN1 and IGN2. This unit is also responsible for the

control of the STARTER relay.

The IBU is also controlling the illumination of the SSB as well as the "system

status indicator", which consists of 2 LEDs of different color. The illumination

of the fob holder is also managed by the SMK.

The IBU reads the inputs (Engine fob in, vehicle speed, relays contact status),

controls the outputs (Engine relay output drivers), and communicates with others

devices via the CAN.

The internal architecture of the IBU is defined in a way that the control of

the terminal is secured even in case of failure of one of the two microcontrollers,

system inconsistency or interruption of communication on the CAN network.

In case, failure of one of the two controllers, the remaining controller shall

disable the starter relay. The IGN1 and IGN2 terminals relays shall be maintained

in the state memorized before the failure and the driver shall be able to switch

those IGN terminals off by pressing the SSB with EMERGENCY_STOP pressing sequence.

However, engine restart will not be allowed. The state of the ACC relay will

depend on the type of failure.

The main functions of the IBU are :

| • |

Control of Terminal relays

|

| • |

Monitoring of the Vehicle speed received from sensor or ABS/ESP ECU.

|

| • |

Control of SSB LEDs (illumination, clamp state).

|

| • |

Control of the base station located in SSB through direct serial interface.

|

| • |

System consistency monitoring to diagnose SMK failure and to switch

to relevant limp home mode.

|

| • |

Providing vehicle speed information

|

| • |

Start Stop Button (SSB) monitoring

|

| • |

Starter power control

|

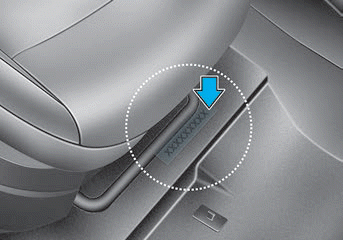

Start/Stop Button (SSB)

A single stage push button is used for the driver to operate the vehicle. Pressing

this button allows:

| • |

To activate the power modes ‘Off’, ’Accessory’, ‘Ignition’ and 'Start'

by switching the corresponding terminals

|

| • |

To start the engine

|

| • |

To stop the engine

|

The contact will be insured by a micro-switch and a backlighting is provided

to highlight the marking of the button whenever necessary.

Two (2) LED colors are located in the center of the button to display of the

status of the system. Another illumination LED is also integrated into the SSB

for the lighting of the "Engine Start/Stop" characters.

Electronic Steering Column Lock (ESCL)

The ESCL is needed to lock the steering column in order to prevent unauthorized

usage of the vehicle. In order to achieve the required safety integrity level,

the ESCL is controlled and monitored by the SMK. Such redundant architecture

guarantees that the ESCL motor is supplied only during locking/unlocking operation

and that it is disconnected from the battery and ground lines otherwise to avoid

unexpected operation while the vehicle is in motion.

Data are exchanged between the ESCL and SMK through an encrypted serial communication

interface.

BES System State Chart

System States in Learnt Mode

In learnt mode, the BES System can be set in 6 different sates, depending on

the status of the terminals, ESCL and Engine status:

|

System State |

Terminal Status |

ESCL Status |

Engine Status |

|

1. OFF - Locked |

OFF |

Locked |

Stopped |

|

2. OFF - Unlocked |

OFF |

Unlocked |

Stopped |

|

3. ACC |

ACC |

Unlocked |

Stopped |

|

4. IGN |

IGN1, IGN2, ACC |

Unlocked |

Stopped |

|

5. Start |

IGN1, Start |

Unlocked |

Cranking |

|

6. IGN - Engine |

IGN1, IGN2, ACC |

Unlocked |

Running (means "self-running") |

Referring to the terminals, the system states described in the table above are

same as those one found in a system based on a mechanical ignition switch. The

one of distinction with Mechanical-Ignition-Switch based system is that the

BES system allows specific transition from [OFF] to [START] without going through

[ACC] and [IGN] states.

System States in Virgin Mode

The BES System can be set in 5 different states (OFF LOCKED is not available

in virgin mode), depending on the status of the terminals, ESCL and Engine status:

|

System State |

Terminal Status |

ESCL Status |

Engine Status |

|

1. OFF - UNLOCKED |

OFF |

Unlocked |

Stopped |

|

2. ACC |

ACC |

Unlocked |

Stopped |

|

3. IGN |

IGN1, IGN2, ACC |

Unlocked |

Stopped |

|

4. Start |

IGN1, START with special pattern of activation see Chap 6.2.1 for details |

Unlocked |

Cranking |

|

5. IGN - Engine |

IGN1, IGN2, ACC |

Unlocked |

Running (means "self-running") |

Referring to the terminals, the system states described in the table above are

same as those one found in a system based on a mechanical ignition switch. The

one of distinction with Mechanical-Ignition-Switch based system is that the

BES system allows specific transition from [OFF] to [START] without going through

[ACC] and [IGN] states.

Other information:

Hyundai Venue (QX) (2020-2025) Service Manual: Components and components location

..

Hyundai Venue (QX) (2020-2025) Service Manual: Front Seat Shield Inner Cover. Repair procedures

Replacement • Put on gloves to prevent hand injuries. • When removing with a flat-tip screwdriver or remover, wrap protective tape around the tools to prevent damage to components...

Categories

- Manuals Home

- 1st Generation Venue Owners Manual

- 1st Generation Venue Service Manual

- Shift-lock system, Shift-lock release, Parking

- Warning and Indicator Lights

- Immobilizer System

- New on site

- Most important about car

Vehicle Identification Number (vin), Vehicle Certification Label

Vehicle Identification Number (vin)

Frame number

Copyright © 2025 www.hvenueqx.com